Inspection staff use secured light sources to carry out full inspections of the woven Igusa sheets that are brought into Suzhou Hagiwara.

The Igusa sheets that pass the inspection are passed through a machine that integrates a dyestuff removing machine, an electrostatic coating machine, and a dryer. All the secondary materials used in the coating machine are imported from Japan.

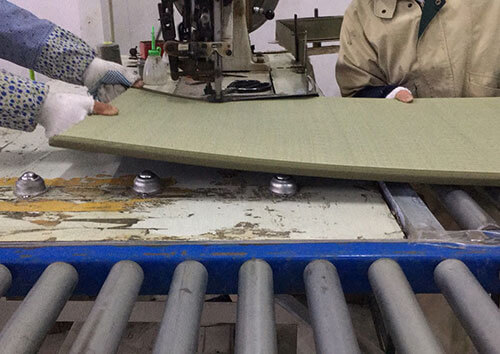

The Igusa sheet is basically rolled or folded, and it is cut to a specific length and width.

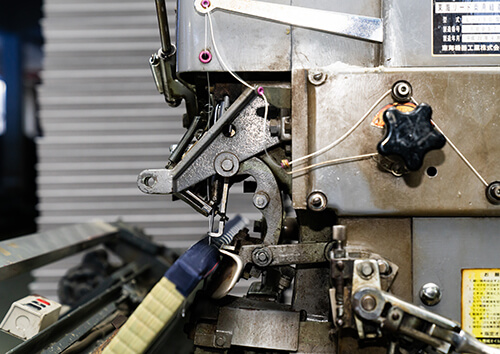

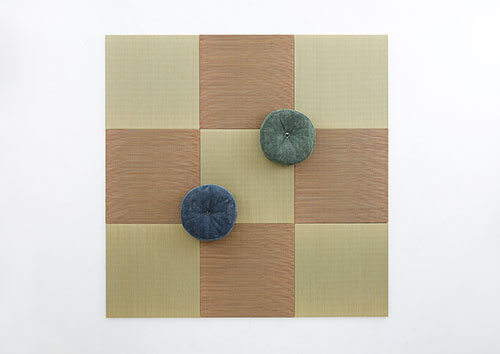

The base material used for tatami mats varies from foamed boards, to insulation boards, felt boards, palm boards and so on. We select the best material according to the thickness and hardness requested by the customer and its intended usage. Then, we attach the Igusa sheet to the base material and stitch the border.

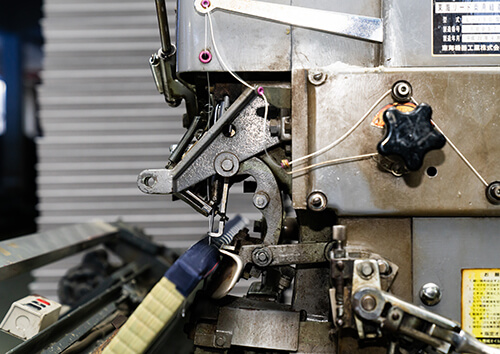

After stitching the border, the frame is sewn. We carefully sew each one using a sewing machine imported from Japan.

The finished product is inspected visually by the inspector.

Packed with waterproof packing material by the packing staff, and in the case of long distance shipments, the corners are covered to prevent damage during transportation.

Inspection staff use secured light sources to carry out full inspections of the woven Igusa sheets that are brought into Suzhou Hagiwara.

The Igusa sheets that pass the inspections are passed through a machine that integrates a dyestuff removing machine, an electrostatic coating machine, and a dryer. All the secondary materials used in the coating machine are imported from Japan and meet food level standards.

The Igusa sheet is basically rolled or folded, and it is cut to the specific length and width.

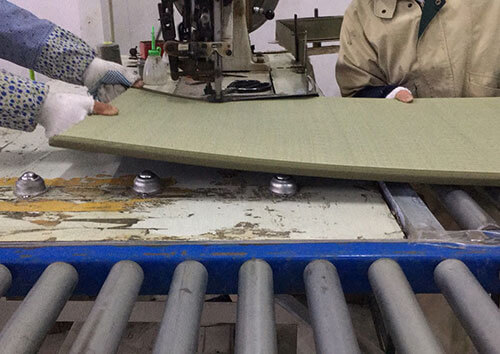

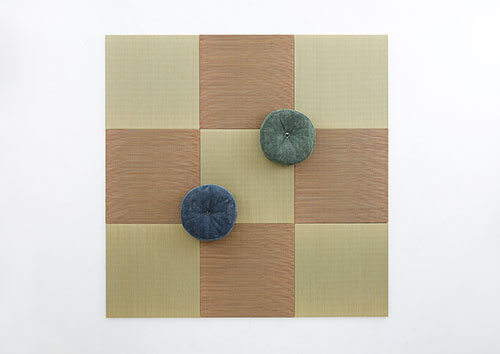

Various materials such as Igusa, paper, PP, and PVC are used for the cover. The base material is also made from all kinds of materials such as foamed boards, insulation boards and felt boards. In this process, the cover and the base material are adhered together using a gluing machine.

。

Flooring tatami mats with frames are sewn with a special sewing machine.

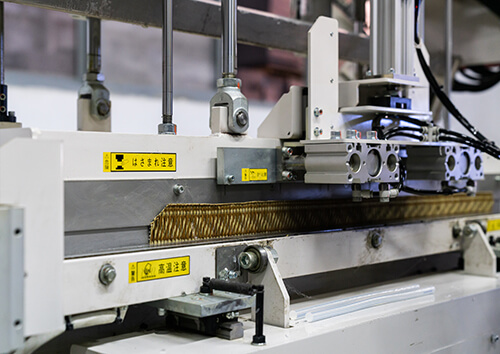

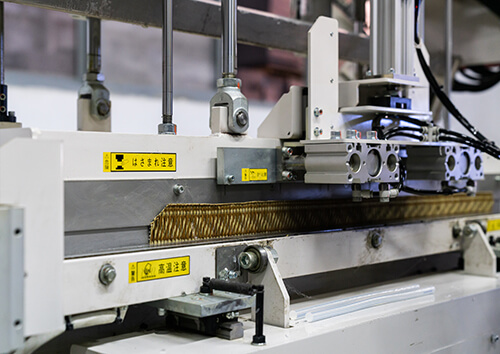

In China, we are the only company which has installed a Japanese-made machine specially designed for frameless flooring tatami mats. This machine makes it possible to fold the edge with straight and tidy lines, and sharpen the corners.

The finished product is inspected visually by the inspector to detect any unexpected needles.

If our customers request it, we attach an acrylic, non-slip grip on the back before packing in cartons.

Inspection staff use secured light sources to carry out full inspections of the woven Igusa sheets that are brought into Suzhou Hagiwara.

The Igusa sheets that pass the inspections are passed through a machine that integrates a dyestuff removing machine, an electrostatic coating machine, and a dryer. All the secondary materials used in the coating machine are imported from Japan and meet food level standards.

The Igusa sheet is basically rolled or folded, and it is cut to the specific length and width.

In order to make 180 x 200cm and 150 x 200cm Igusa sleeping mats, two Igusa mats are combined into one, and the size of the frame is adjusted according to the customer’s request. Rubber mattress grips and a quality indication label are also attached in this process.

The finished product is inspected visually by the inspector to detect any unexpected needles.

We will pack with packing materials according to customer’s requests.

We inspect the quantity and damage status when we store finished products and semi-finished products. About 400 rolls of raw material are inspected per day.

Full-time inspection staff carry out thorough inspections of the Igusa sheets (woven, semi-finished products) during the day, when a sufficient light source is secured.

Product inspection, Needle Detection

The finished product is visually inspected again according to Japanese standards by a full-time inspector, and a final inspection is performed with a needle detector.

Various warehouse services

In the warehouse, we conduct inspections, as well as making labels, labeling, attaching price tags, packing and so on.

Secure long-term storage in a large space

Inspected products are stored in a spacious warehouse exceeding 17,000 m3. We also accept long-term storage.

Know-how and Achievements accumulated for years

We import around 270 TEU containers annually.

Proposal to be an OEM that uses technology developed with Japanese quality

Proposal to be an ODM that manufactures Japanese standard products designed by Japanese designers

Proposal to create our original products considering sales strategy and planning to meet customer’s requests

Please feel free to contact us regarding online sales (Tmall, JD.com, and Alibaba), B2C, B2B, agency sales and so on.

We have a sales team specialized in customized tatami mats. Please do not hesitate to contact us for any requests including personal use, reconstruction, store remodeling, agency sales and so on.

We also exhibit at exhibitions, department stores, and mass retailers. Please come and visit us when the opportunity arises.。

IGUSA is planted in paddy fields from mid-November to mid-December.

IGUSA is harvested from early June to mid-July.

To become the unique color, aroma, and luster of IGUSA, the harvested IGUSA is mud-dyed with natural soil within the same day, and then dried,

Inspection staff use secured light sources to carry out full inspections of the woven Igusa sheets that are brought into Suzhou Hagiwara.

The Igusa sheets that pass the inspection are passed through a machine that integrates a dyestuff removing machine, an electrostatic coating machine, and a dryer. All the secondary materials used in the coating machine are imported from Japan.

The Igusa sheet is basically rolled or folded, and it is cut to a specific length and width.

The base material used for tatami mats varies from foamed boards, to insulation boards, felt boards, palm boards and so on. We select the best material according to the thickness and hardness requested by the customer and its intended usage. Then, we attach the Igusa sheet to the base material and stitch the border.

After stitching the border, the frame is sewn. We carefully sew each one using a sewing machine imported from Japan.

The finished product is inspected visually by the inspector.

Packed with waterproof packing material by the packing staff, and in the case of long distance shipments, the corners are covered to prevent damage during transportation.

Inspection staff use secured light sources to carry out full inspections of the woven Igusa sheets that are brought into Suzhou Hagiwara.

The Igusa sheets that pass the inspections are passed through a machine that integrates a dyestuff removing machine, an electrostatic coating machine, and a dryer. All the secondary materials used in the coating machine are imported from Japan and meet food level standards.

The Igusa sheet is basically rolled or folded, and it is cut to the specific length and width.

Various materials such as Igusa, paper, PP, and PVC are used for the cover. The base material is also made from all kinds of materials such as foamed boards, insulation boards and felt boards. In this process, the cover and the base material are adhered together using a gluing machine.

Flooring tatami mats with frames are sewn with a special sewing machine.

In China, we are the only company which has installed a Japanese-made machine specially designed for frameless flooring tatami mats. This machine makes it possible to fold the edge with straight and tidy lines, and sharpen the corners.

The finished product is inspected visually by the inspector to detect any unexpected needles.

If our customers request it, we attach an acrylic, non-slip grip on the back before packing in cartons.

Inspection staff use secured light sources to carry out full inspections of the woven Igusa sheets that are brought into Suzhou Hagiwara.

The Igusa sheets that pass the inspections are passed through a machine that integrates a dyestuff removing machine, an electrostatic coating machine, and a dryer. All the secondary materials used in the coating machine are imported from Japan and meet food level standards.

The Igusa sheet is basically rolled or folded, and it is cut to the specific length and width.

In order to make 180 x 200cm and 150 x 200cm Igusa sleeping mats, two Igusa mats are combined into one, and the size of the frame is adjusted according to the customer’s request. Rubber mattress grips and a quality indication label are also attached in this process.

The finished product is inspected visually by the inspector to detect any unexpected needles.

We will pack with packing materials according to customer’s requests.

We inspect the quantity and damage status when we store finished products and semi-finished products. About 400 rolls of raw material are inspected per day.

Full-time inspection staff carry out thorough inspections of the Igusa sheets (woven, semi-finished products) during the day, when a sufficient light source is secured.

Product inspection, Needle Detection

The finished product is visually inspected again according to Japanese standards by a full-time inspector, and a final inspection is performed with a needle detector.

Various warehouse services

In the warehouse, we conduct inspections, as well as making labels, labeling, attaching price tags, packing and so on.

Secure long-term storage in a large space

Inspected products are stored in a spacious warehouse exceeding 17,000 m3. We also accept long-term storage.

Know-how and Achievements accumulated for years

We import around 270 TEU containers annually.

Proposal to be an OEM that uses technology developed with Japanese quality

Proposal to be an ODM that manufactures Japanese standard products designed by Japanese designers

Proposal to create our original products considering sales strategy and planning to meet customer’s requests

Please feel free to contact us regarding online sales (Tmall, JD.com, and Alibaba), B2C, B2B, agency sales and so on.

We have a sales team specialized in customized tatami mats. Please do not hesitate to contact us for any requests including personal use, reconstruction, store remodeling, agency sales and so on.

We also exhibit at exhibitions, department stores, and mass retailers. Please come and visit us when the opportunity arises.

IGUSA is planted in paddy fields from mid-November to mid-December.

IGUSA is harvested from early June to mid-July.

To become the unique color, aroma, and luster of IGUSA, the harvested IGUSA is mud-dyed with natural soil within the same day, and then dried,